A Warehouse Slotting Primer

Warehouse slotting is the science, along with a dash of art, behind organizing inventory by key characteristics such as turnover frequency, fragility, product type, pick-face size, dimensions, and expiration date among others in order to maximize the efficiency of picking. Think about how you slot your toolbox: That “go to” Philips screwdriver you use all the time is in the topmost slot, those weird needle-nose pliers you used once to start your neighbor’s ancient lawnmower are in one of the lower slots, the fancy Snap-on brand adjustable wrench which you take out just to ogle sometimes is in a special latched slot away from the other “regular” tools, and the clunky hammer is naturally at the middle-bottom of the box in the same spot as its rusty outline. The same basic idea applies in warehouse slotting.

At both macro (pick zone) and micro levels, slotting should be an important aspect of your overall inventory management strategy. We will look at the major benefits in a bit, but one big underrated ergonomic plus is that your warehouse personnel – and their creaky joints – will thank you due to less bending, twisting, and other grimace-inducing contortions. It should be noted that with an automated high-density rack system you might be at the mercy of FIFO, but for everyone else let’s talk slotting.

It sounds like a 1980s arcade game, but the golden zone (pictured at the top of the article) is the optimal level where your warehouse staff can most effortlessly pick inventory. This is roughly chest-height on the average person, and it is here where the fastest moving stock should be stored.

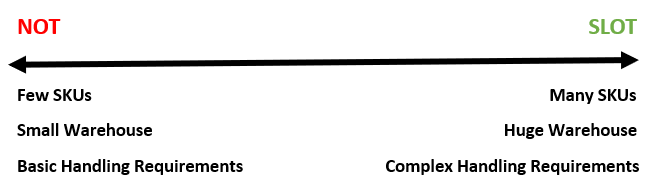

In the Warehouse Management System World…

WMS users specify slotting locations and if they don’t, then the system relies on location dimensions and product storage rules to determine location. Warehouse Management Systems handle a lot by nature, but even with the best tier-1 WMS in place your team should still have a slotting strategy in place that is reviewed on an ongoing basis as things inevitably change. You would of course use select data in the WMS, especially turnover-per-item, to inform your decisions.

Why Slotting?

Faster, more accurate picking – There is less guesswork, bottlenecks, and more economical movement by the picker(s) when inventory is optimally located, and at the end of the day faster picking contributes to faster overall customer order fulfillment

Less carrying/handling costs – Moving around within a warehouse consists of the majority of a picker’s time, and those valuable hours can be saved via efficient picking that includes less travel distance for pickers. More inventory in less space also reduces cost on the storage side as well

Better storage optimization – Storing inventory in a strategic and organized manner results in better utilization of space versus no plan or methodology

Less shrinkage – Make finding inventory easier and you will have fewer items lost in the shuffle, and storing heavier items at-or-near the bottom of the rack (cart level) should result in less stock tumbling to its doom

Slotting Methods:

Random Slotting

Random slotting basically means that whoever is stowing the inventory can put items in locations of their choosing, with the advantages that the travel distance is reduced, the chance of an error related to item(s) being put in the wrong location is lessened, and flexible location assignment means less stock over-saturation in certain areas and less under-saturation in others – which in-turn means better utilization of free space in the warehouse. This method is especially ideal if you have frequently changing stock stemming from seasonality or demand shifts, and is the simplest path for loading dock personnel as they can both receive and then immediately put away the stock. You must have a WMS in place for slotting randomly, as warehouse personnel would have a hard time quickly tracking down inventory without one. But really, you should probably have a WMS anyway.

Fixed (aka Static) Slotting

In fixed slotting a permanent bin location is assigned to for each item. This practice makes the most sense for rarely-changing warehouses that mainly move a select few items of high-turnover stock.

Dynamic Slotting

Dynamic slotting allows for item locations to be changed, which of course can happen depending on turnover frequency, wave pick requirements, and/or if newly added stock is introduced. If warehouse personnel know that they will soon have many picks for a specific type of stock and/or if there are not enough existing pick locations to handle an unusually big influx of a certain item, then they could create a temporary slot near the picking area to save time.

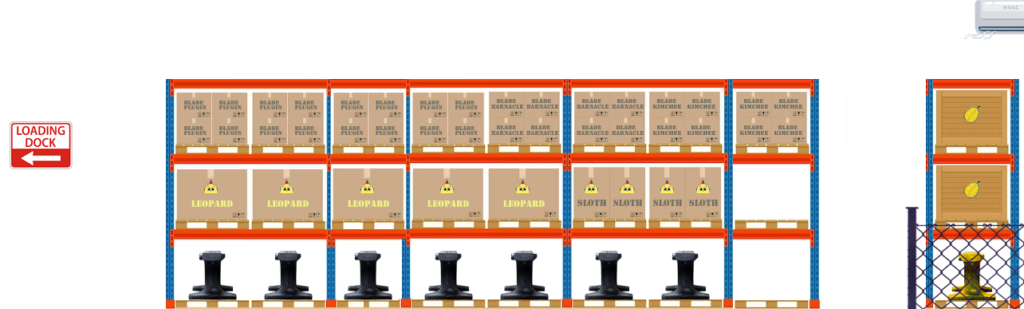

Basic Slotting Example of a Small-Medium Warehouse with an Eclectic Array of Items:

- 1st Best-selling item pet chicken speedos in top selling leopard print and less popular “sloth print”

- 2nd Best-selling item “Blade” Plug-ins air fresheners frequently sold with “Dry Barnacle” and equally popular “Leftover Kimchee” scented refill filters

- Medium-selling standard anvils

- Rarely-sold solid gold anvils

- Poor-seller premium dried durian fruit (sold by the crate)

|

Our goal isn’t to necessarily strictly adhere to slotting rules, but instead to have an overall slotting strategy for our warehouse and end up with something that works for us. So…What do we put where?

The pet chicken speedos in leopard print are flying off the shelves, and so we need to put them at an easily accessible level on our rack and preferably as close as possible to the loading dock. Sloth print is less popular than leopard, but it moves faster than other products and so we’ll put it right next to our leopard print offering.

Our next most popular product is Blade PlugIn air fresheners, which we put right above our pet chicken speedos in a relatively easy spot to pick from near our loading dock. The barnacle and kimchee scented refills are right next-door since they are frequently kitted together with the main unit plugin.

The anvils are the next most popular item, and they earned a prominent pick location as well. We put them closer to cart-level due to ease-of-wrangling onto a cart and for safety reasons. The gold anvil offering rarely sells, and so we can put that slow-mover in another section of the warehouse and behind a fence due to its high value.

Our operation also ships out dried durian fruit by the crate, which doesn’t need refrigeration but should have some temperature and humidity control and so we put that in an environmentally controlled area which – due to our warehouse size and layout – also happens to be in our high security zone.

Let us know your thoughts on this article or perhaps we can swap slotting strategies; either way feel free to please drop us a line!

This post was written by:

Recommended Content

A Guided Tour of Supply Chain Execution Systems

Supply Chain Execution (SCE) systems are behind the process workflows of goods going from procurement to delivery in the supply chain. SCE comes after Supply Chain Planning (SCP), and both are under the umbrella of Supply Chain Management (SCM) systems. In this...

WMS Go Live Checklist Download

Keep in mind that this checklist is a starting point. Adapt it to fit your WMS project's specific needs. Understand your project's unique requirements and customize the checklist accordingly.

Performance Testing Your Warehouse Management System

We’ve made the case for automated testing in various blog articles with a regression testing focus, but we can’t neglect the importance of performance testing. It’s critical for warehouses to determine for their supply chain systems an answer to the question: At what...

Top 5 Ways You Could Botch Your Next WMS Go Live

Are things running too smooth? Have you had it too easy in the supply chain world these days, and want to challenge yourself by botching a warehouse management systems go live? Certainly technology has evolved to the point where we can simply press a button and have...

13 Burning Questions for a Pioneer in Warehouse Modernization

Trevor Blumenau is a professional engineer with a master’s degree in robotics from UC Berkeley and has 25 years of R&D experience in warehouse/manufacturing processes, controls, and innovation. Trevor founded Voodoo Robotics to modernize warehouse operations by...