Automated Testing Makes for Less Risky WMS Rollouts

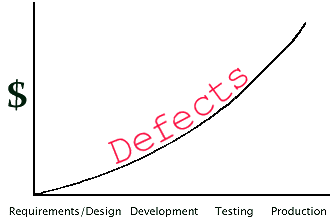

Defects cost time and money, whether it’s a problem in your process or configuration, or more commonly in the form of a software failure or bug. As the graph above shows, defects only get more expensive in terms of downtime(s), labor intensiveness, and reputation damage the longer they persist. There is a key “cost avoidance” metric called defect leakage percentage which measures the how many defects were “leaked” from testing to production, and everyone – except your merciless competition that hate-watches your operation’s every move with bloodlust in their eyes – wants this number to be as low as possible. Consider the ramifications of a software defect that prevents picking found via a nightly test, versus if that same issue was discovered in production after a go live.

Automated testing is, simply put, automating the execution and pass/fail reporting of repetitive tests against a system under test with the end goal of catching potentially costly defects as early as possible. Manual testing is fine for those rare edge cases, visual acceptance testing, and when conducting exploratory testing, but it can be laborious, pricey, and inconsistent if it is performed regularly to test an entire system. Automated testing is faster (more tests run in less time), more accurate, and cheaper while allowing for much greater test coverage and reporting capabilities than manual testing. Whether regression or performance testing, manual testing can’t be solely relied upon to test – and in-turn reduce business risk for – warehouse management systems in a timely manner due to the overall complexity of such a deep, enterprise-wide application.

Reasons for including automated testing in your WMS projects:

|

|

What types of tests are the most ripe for automation?

- Older, repetitive tests that have crystal clear pass/fails for verification and/or validation. A good example would be a test case that tries various username and password combinations for the WMS Web interface.

- Data-driven tests and/or any test that requires lengthy, in-depth preparation. Things like configuring and cleaning up large volumes of test data, or the submissions of lengthy forms with various combinations of input data. Let your test automation solution take the brunt of the repetitive configuration management workload.

- Sanity and smoke tests, especially any typical paths that your users take through the system under test. For example, you should make doubly sure that warehouse personnel can pick the top three best-selling products.

- Time-consuming tests that involve lengthy and repetitive user interactions. Not only is it expensive to tie up a human tester with long, monotonous tests like this, but over time the manual tester becomes glassy-eyed and bored from mindlessly clicking – and in-turn the overall quality of testing drops.

- Performance tests, as the very nature of determining speed, reliability, scalability, and resource usage is what automated tests are perfectly designed to tackle. The process of finding system benchmarks demands the consistency and precision afforded by automated testing. After the big network upgrade, does the WMS crash when a large team of warehouse personnel are all performing receiving, putaway, and picking operations at the same time?

Remember, good test cases have…

- A clear objective with a refined scope

- Obvious and meaningful pass/fail verifications

- Clear and concise documentation

- Traceability to requirements

- Reusability

- Independence from other test cases while testing one thing

- Permutations taken into account by the test case designer

Can your team get away with manual testing just the most critical WMS processes? The answer to that question: It’s risky but…possibly? Plenty of go lives and upgrades have been successful at the end of the day without adequate test coverage, though there was usually some unnecessary nail-biting and at least a few disruptive bumps in the road that could have been otherwise smoothed out in advance. Plenty of rollouts have also bombed due to major defects that reared their ugly head in production which could have been caught earlier with the increased test coverage afforded by automated testing. As profits, as well as jobs, are on the line we think automated testing is worth the extra initial “transitional effort” to drastically reduce business risk. Are you in the market for less risky WMS go lives or upgrades, and/or looking for a test automation solution? Drop us a line!

This post was written by:

James Prior Sales Ops Manager James has been working in software pre-sales and implementation since 2000, and more recently settled into working with a pre-sales team and occasionally writing blog posts. Drop him a line at: james.prior[at]tryonsolutions[dot]com.

Recommended Content

Successfully Upgrading to Blue Yonder SaaS Despite Mid-Project Scope Expansion

This case study explores how our team successfully managed and completed a Blue Yonder SaaS upgrade despite significant mid-project scope expansion. Discover the challenges faced, strategic adjustments made, and best practices applied to keep the project on track,...

6 Levers for Smarter WMS Support

Whether you're juggling school drop-offs, remembering a birthday party, or trying to reply to that one group text before dinner hits the table, modern life pulls us in a hundred directions at once. That constant pressure to keep up, stay flexible, and deliver—no...

Executive Checklist – Is Your WMS Supporting Business Strategy

This executive checklist from Tryon Solutions helps leadership teams assess whether their Warehouse Management System is truly aligned with business strategy. Explore key areas like scalability, customer experience, operational efficiency, and innovation to identify...

From Cost to Value-An Executive Guide to WMS ROI

Unlock the full ROI of your WMS with this executive guide from Tryon Solutions. Discover how services like testing, integration, and continuous optimization drive long-term value far beyond go-live.

WMS Lift-and-Shift the Top 10 Reasons to Move from On-Prem to SaaS

Over the last couple of years there has been a major push on all enterprise systems to move to the cloud. This includes ERP, CRM, HRIS, PLM, SCM, BI, MES, etc. The acronyms could go on forever. Each organization has their reasons for the move, but most fit into three...