A Big Question for Multi-Warehouse WMS Implementations

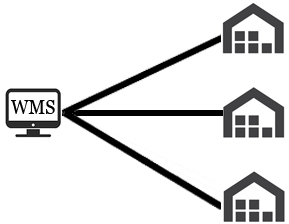

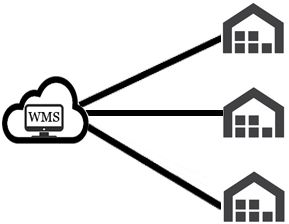

The strategic planning stage is obviously critical for WMS implementations, and one commonly glossed over aspect is multi-warehouse configurations. The implementation team is focused on the success of the first site with both budget and timeline crunches in mind, and they lose sight of the overall big picture. That first, single site is simply one part of a multi-year global WMS rollout strategy. It’s much harder to change the tires mid-race on this one, so let’s get it right the first time. There are a nearly infinite number of variations on the below setups, but whether on-premise or cloud hosted let’s break down the two main options:

Implement Warehouses Within the Same Instance:

Good

- Simplifies IT maintenance (hotfixes, patches, etc…)

- Streamlined “big picture” visibility across all warehouses

Bad

- All sites share risk of introducing new functionality that might just benefit one site

- Not ideal for coordinating maintenance downtimes across different time zones

Bottom Line

This option can make sense for a smaller operation with limited IT resources that has fewer customers and sites that are all in roughly the same geographic area.

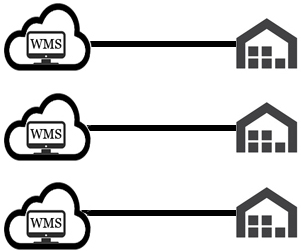

Each Warehouse in Own Independent Instance and Server:

Good

- Better for a 3pl servicing multiple clients with varying requirements

- Drastically less risk in the event of a major defect

Bad

- More work on the IT side

- Less big-picture visibility

Bottom Line

Due to the extreme riskiness of the “all-in-one” method, most medium-large warehouses are forced to adopt this strategy.

After Answering That Question…Do You Cloud?

Good

- Easier to receive product updates

- Easier to scale up resources with company growth

- Generally, less likely to experience IT-related outages

Bad

- Provider MUST have fast-responding quality support

- Provider MUST have secure data

Bottom Line

The answer is “probably.” In recent years we are seeing more customers move to the cloud. If you must be up-to-date on the latest features and tech, go with the cloud option. Should you have a basic setup and want to keep things in-house, then consider going on-premise.

There are many ways to skin a cat for multi-warehouse implementations, so consider the above as the main umbrella options and not cast in-stone. You especially have to have all internal and external stakeholders aligned before diving in and setting a direction for a multi-warehouse implementation versus a single operation install.

How do you handle multi-warehouse implementations? Feel free to drop us a line if you have any questions, or feedback on this post! We are an official reseller of Blue Yonder WMS, and provide the full gamut of related WMS professional services.

This post was written by:

Recommended Content

A Guided Tour of Supply Chain Execution Systems

Supply Chain Execution (SCE) systems are behind the process workflows of goods going from procurement to delivery in the supply chain. SCE comes after Supply Chain Planning (SCP), and both are under the umbrella of Supply Chain Management (SCM) systems. In this...

WMS Go Live Checklist Download

Keep in mind that this checklist is a starting point. Adapt it to fit your WMS project's specific needs. Understand your project's unique requirements and customize the checklist accordingly.

Performance Testing Your Warehouse Management System

We’ve made the case for automated testing in various blog articles with a regression testing focus, but we can’t neglect the importance of performance testing. It’s critical for warehouses to determine for their supply chain systems an answer to the question: At what...

Top 5 Ways You Could Botch Your Next WMS Go Live

Are things running too smooth? Have you had it too easy in the supply chain world these days, and want to challenge yourself by botching a warehouse management systems go live? Certainly technology has evolved to the point where we can simply press a button and have...

13 Burning Questions for a Pioneer in Warehouse Modernization

Trevor Blumenau is a professional engineer with a master’s degree in robotics from UC Berkeley and has 25 years of R&D experience in warehouse/manufacturing processes, controls, and innovation. Trevor founded Voodoo Robotics to modernize warehouse operations by...