TRYON BLOG

Why Would You Need a Transportation Management System?

Delivering a product to the right place at the right time can require more than just a system that optimizes everything within the walls of a warehouse, and so let’s answer the question: Why would you need a Transportation Management System?

Meeting customer service levels these days often demands a higher level of speed, visibility, intelligence, and agility throughout the entire supply chain journey. Think about it…If you use a WMS and are optimizing the processes and movements behind inventory moving through your warehouse, why should the optimization cease when the goods ship out from the dock? In this era of capacity crunches, labor shortages, port congestion, rising fuel costs, and demanding “ship it yesterday” e-commerce we must also look at the transportation side of the house.

A Transportation Management System is a logistics platform that helps manage, execute, and optimize the inbound and outbound flow of goods. It can also give visibility into all fleet operations (land, sea, and air), including compliance and documentation, to ensure on-time deliveries. The goal of a TMS is to improve shipping efficiency, reduce cost, and improve customer satisfaction. After a WMS, arguably the next most critical supply chain execution system for a warehouse that ships product is a TMS. They should be integrated together to maximize the benefits of both systems.

Key Benefits of a Tier-1 TMS

- Improved, load-optimized on-time deliveries

- Reduced overall cost of logistics

- Better, more streamlined visibility and freight tracking

- Automated billing and documentation processes are faster and more accurate

- Ability to use models that can help catch supply chain issues in advance

- Allows for measuring of transportation related KPIs

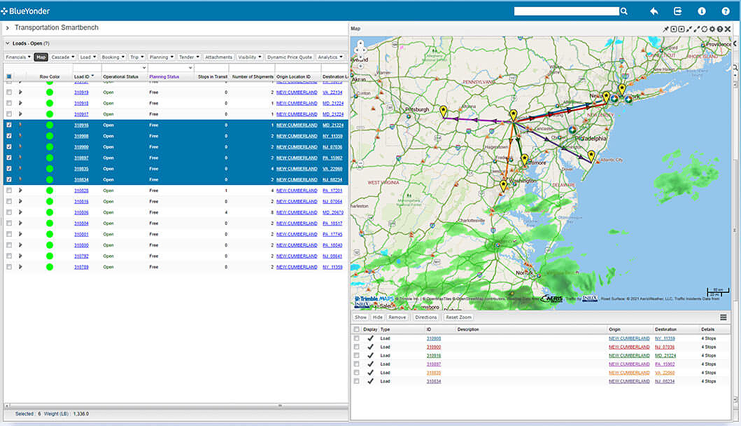

Blue Yonder TMS

Planning and Execution

A TMS allows for more strategic planning, better execution, and improved optimization for inbound and outbound processes in both regional and global scope. You have streamlined procurement and freight shipment with automated carrier rate comparisons, negotiation and booking – and you can also choose the mode of shipment and the most efficient route. This eliminates time-consuming and potentially inaccurate manual processes behind tracking down the best mode of shipment at the best price. The TMS will also help optimize the load, and later you can real-time track/monitor and trace the shipment all the way to its destination.

Freight Management

A TMS helps with managing orders, freight costing, determining rates, billing, and settlement for both multimodal and intermodal transportation. It is much more efficient to settle disputes through the TMS partner network, especially as opposed to the old days of angry back-and-forth phone calls.

Analytics

With a tier-1 TMS you can forecast transportation demand, analyze rates, and basically have visibility into all aspects of the transportation process, and this allows your team to be more informed and agile in your decision making. A TMS also helps with measuring and tracking of Key Performance Indicators like transportation time, percent trucking capacity, claims versus freight costs, and pickup/delivery times. They are all directly related to the success of the transportation side of the business, and its critical to continuously improve from established baselines to targets.

Do I Need a TMS?

If you are a medium-to-large shipper then you MUST at least seriously research and evaluate the ROI for TMS adoption at your operation. Read through this article using it as a primer, and then check out Blue Yonder and other companies in the supply chain execution space with TMS offerings.

Real-World Example

Retail gargantuan Wal-Mart identified the need to standardize its end-to-end transportation processes across operating regions, increase responsiveness to time-sensitive customer demands, and consolidate trucking routes where appropriate. Their ultimate goals were to save money and reduce emissions, and by implementing a tier-1 TMS (Blue Yonder brand in this case) they doubled their overall fleet efficiency resulting in a whopping one-billion US dollars per year savings.

A TMS is certainly worth considering if your operation is a medium-to-large 3pl or if you have many customers in a variety of destinations and you handle your own logistics. If you need help streamlining your logistics and/or are in the market for a TMS, please drop us a line!

Written By James Prior

With over two decades in software pre-sales and implementation, James specialized in working with the sales team and contributed to blog posts. For further information, please email sales@tryonsolutions.com.

More From This Category

6 Levers for Smarter WMS Support

Whether you're juggling school drop-offs, remembering a birthday party, or trying to reply to...

WMS Lift-and-Shift the Top 10 Reasons to Move from On-Prem to SaaS

Over the last couple of years there has been a major push on all enterprise systems to move to...

5 Signs Your Software May Not Be FSMA Rule 204-Compliant

Is your current software keeping up with the new requirements of FSMA Rule 204? If you're not...